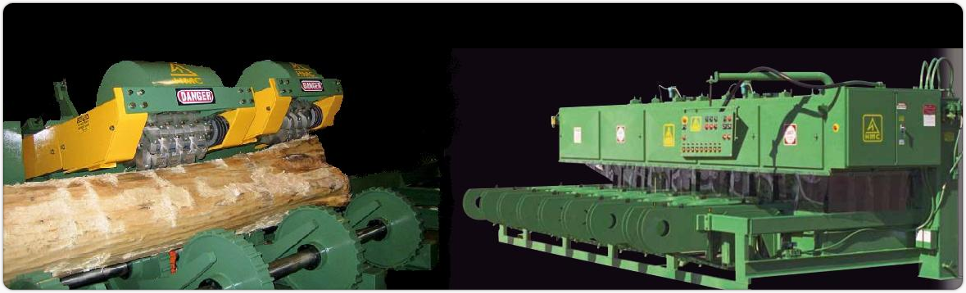

APPLICATION: For end trimming lumber, cants or ties up to a 9” thickness.

View the HMC ET-10 HS Trimmer Brochure

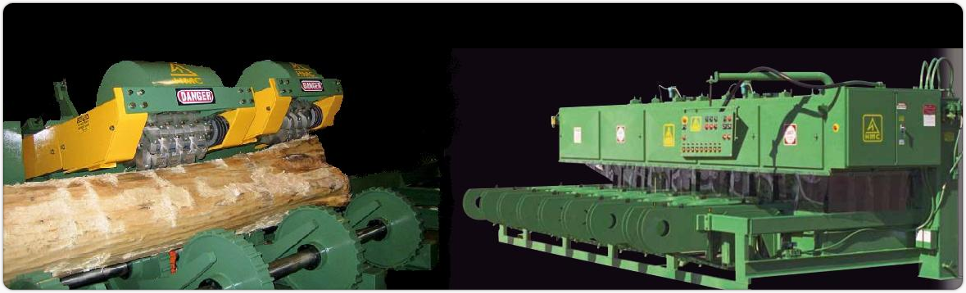

SPECIFICATIONS:

Tubular frame construction with wide flange beam upright supports.

Feed chains are #80 roller chain, powered via 3HP variable speed drive.

Strands are running on nylon slides and are moved via #60 roller chain.

Saws are 30” carbide, powered by 10HP TEFC saw arbor motors. Four (4) saws are included.

5HP variable speed electric vector drive for shifting saw.

HMI for set-up and programming.

Programmable 18 button setworks.

Drive enclosure with disconnect, includes 25’ of cabling.

Wiring for moveable strand contained within cable carrier.

Unit is pre-wired and tested at the factory.

OPTIONS:

Powered center strand

Belt conveyor with 2HP electric drive, not built into trimmer (18” wide belt)

Extra sets for setworks (each)

10” leg extension (required when belt is installed in trimmer)

Additional saws are available (Check with factory for current pricing.)

APPLICATION: For end trimming lumber, cants or ties up to a 9” thickness.

View the HMC ET-10 HS Trimmer Brochure

See one in action on Youtube.

SPECIFICATIONS:

- Tubular frame construction with wide flange beam upright supports.

- Feed chains are #80 roller chain, powered via 3HP variable speed drive.

- Strands are running on nylon slides and are moved via #60 roller chain.

- Saws are 30” carbide, powered by 10HP TEFC saw arbor motors. Four (4) saws are included.

- 5HP variable speed electric vector drive for shifting saw.

- HMI for set-up and programming.

- Programmable 18 button setworks.

- Drive enclosure with disconnect, includes 25’ of cabling.

- Wiring for moveable strand contained within cable carrier.

- Unit is pre-wired and tested at the factory.

OPTIONS:

- Powered center strand

- Belt conveyor with 2HP electric drive, not built into Trimmer (18” wide belt)

- Extra sets for setworks (each)

- 10” leg extension (required when belt is installed in Trimmer)

- Additional saws are available (Check with factory for current pricing.)